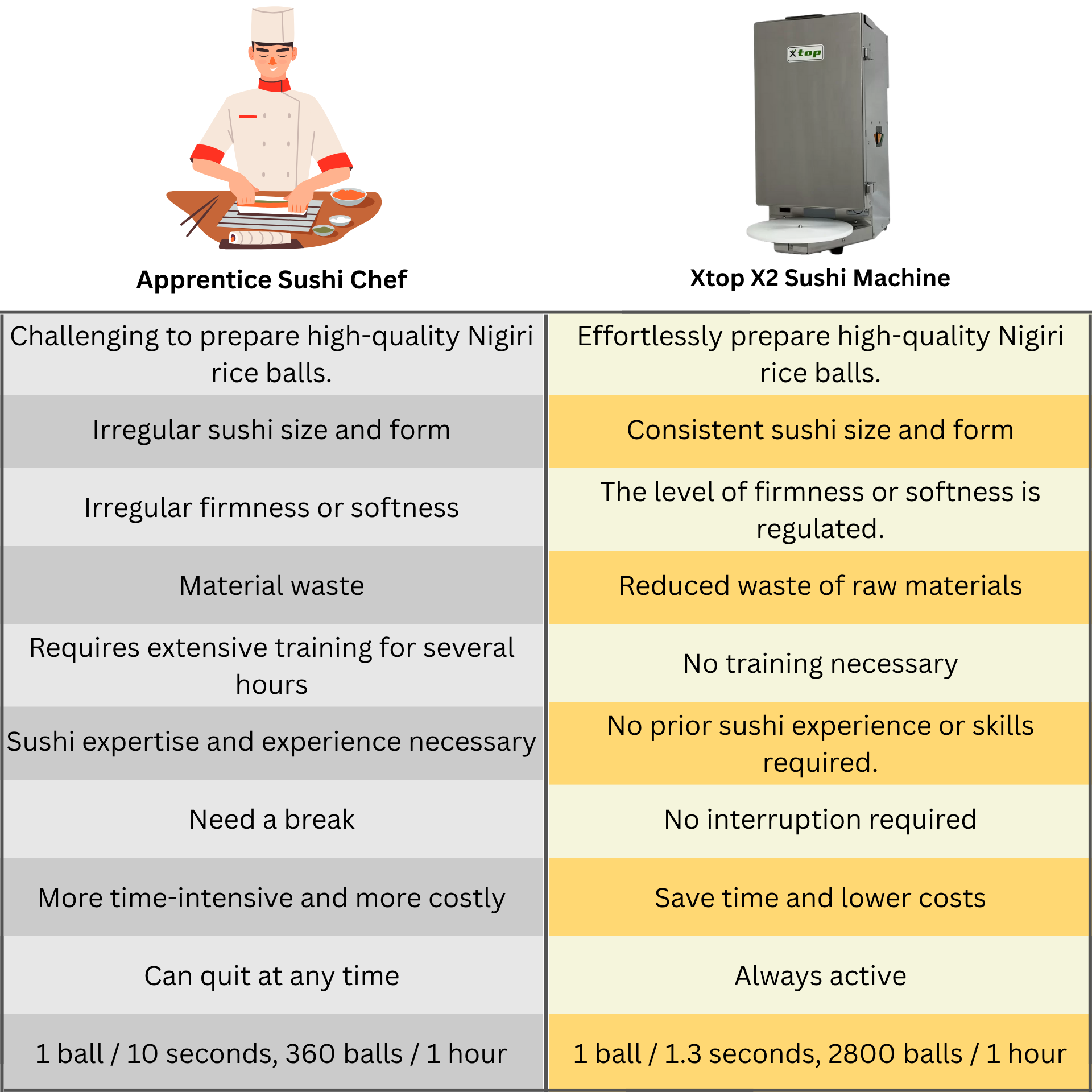

Sushi Forming Machine - Standardize Quality, Speed Up Process, Save Labor and Cost

Sushi forming machine with capacity of 2800 balls/hour and rice capacity of 4.5kg. There is a knob to adjust the hardness of the sushi. The sensor stops the turntable automatically when 6 sushi balls are created. The size of the sushi rice can be changed by changing the forming roller.

In the modern F&B industry, maintaining consistent product quality, saving labor costs and increasing efficiency are key requirements. For Japanese restaurants, sushi bars or Asian food chains, high-capacity industrial sushi rice presses are an indispensable assistant. The sushi rice press with a capacity of 2800 pieces/hour, a rice container capacity of 4.5kg and a compact design, has been and is being considered the optimal solution for modern business models.

**Sushi Chef Salary from TopCV (May 2025) and Sushi Chef Cost are calculated based on Employer-paid costs (including insurance %)

**Equipment manufactured in Japan has an average lifespan of at least 5 years

Cost of Xtop X2 Sushi Rice Maker (including VAT) and Apprentice Sushi Chef after 9 months and 9 days:

130 + 9 x 9.3 ~ 214 million VND

Cost of Professional Sushi Chef after 9 months and 9 days:

23 x 9.3 ~ 214 million VND

Based on a comparison of labor costs between an apprentice sushi chef and a professional chef, the investment in sushi equipment will pay back after 9 months and 9 days

The sushi rice shaping machine integrates a system of 3 pairs of rice feeding rollers combined with 11 mixing bars to help separate the rice evenly and continuously shape it, without being lumpy or compressed too much. In particular, the dual torsion force holding system has the function of pushing the rice evenly, creating Nigiri rice balls with a firm structure, meeting the requirements of both appearance and feeling when eating.

The rice ball shaping technology (patented) allows the sushi machine to produce products with uniform size, weight and compression, almost no different from the products made by hand by professional sushi chefs.

The two central rollers play a role in adjusting the amount of rice fed into the mold, allowing the operator to flexibly adjust the compression (hardness/softness) of the Nigiri rice according to the menu requirements.

The automatic sushi machine operates with a maximum power consumption of only 90W, using AC220–240V / 50Hz power source, suitable for the electrical infrastructure conditions of most restaurants and processing facilities today. At the same time, the device meets international standards such as UL, CSA, NSF and CE, ensuring safety and reliability in long-term operation.

The entire main part of the professional rice straightener is made of SUS 304 stainless steel, ensuring superior durability and corrosion resistance in humid, salty and mildly acidic working environments such as when making sushi. The rice hopper is coated with Dupont's high-quality Teflon, which is effective in preventing sticking and easy to clean after each use.

The sushi machine is equipped with a motor made in Japan, integrated with a self-protection function when overloaded or overheated, helping to prolong the life of the device and reduce the risk of continuous operation. Waterproof and oil-proof sensor meets IP67 standard, increasing stable operation in professional kitchen environment.

With a size of only 300x480x590mm and a weight of 26kg, the sushi machine can be flexibly arranged in many locations in the kitchen or processing counter without taking up much space. The device is especially suitable for Japanese restaurants, central kitchens of sushi chains, and Japanese-style fast food models.

The sushi machine creates many sizes of rice balls

16-18-20g: Recommended for high-end Japanese sushi restaurants. With smaller sizes, diners need to eat more pieces to feel full and satisfied.

20-22-24g: Recommended for supermarkets or takeaway sushi models. This is the most standard size, helping diners easily enjoy Nigiri sushi while still ensuring satisfaction.

22g-24g-26g: Suitable for sushi buffet restaurant model. This size helps diners feel full faster.

30g: Recommended for Inari sushi. This is the size that gives the dish the most eye-catching, luxurious and familiar appearance.

30-40g: Cylindrical shape, used for traditional Japanese lunch boxes (Bento/Makunouchi Bento). This size and shape is suitable for beautiful arrangement in portioned lunch boxes.

main.comment_read_more